Home > News

Home > News

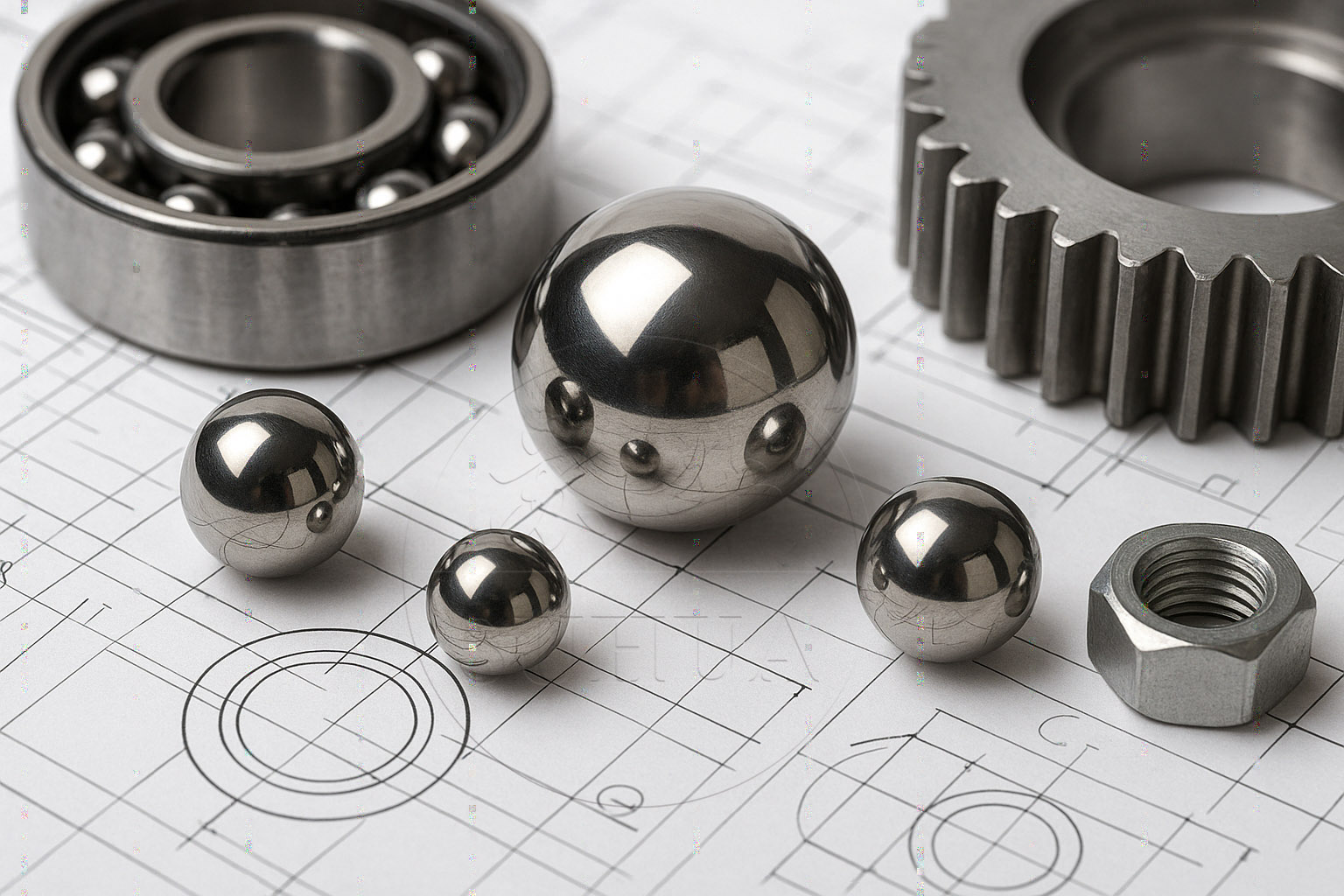

In the world of industrial manufacturing, balls may appear small, but they play a crucial role in bearings, valves, measuring devices, conveyors, and even consumer products. The performance of these balls directly affects the efficiency, reliability, and lifespan of the entire system. With the diversification of industrial applications, selecting the right material has become a critical challenge. To guide this process, the industry often relies on the “Golden Triangle Principle” — Strength, Corrosion Resistance, and Cost.

Strength is the first criterion in choosing balls, ensuring stability under high speed, heavy loads, or impact conditions.

Bearing Steel Balls (High Carbon Chrome Steel, e.g., GCr15)

Known for hardness, wear resistance, and fatigue strength, widely used in bearings, automotive parts, and machinery.

Tungsten Carbide Balls

Extremely hard and wear-resistant, ideal for mining, oil, aerospace, and extreme wear environments.

Ceramic Balls (Si₃N₄, ZrO₂)

Lightweight yet strong, with low friction and high-temperature stability, widely applied in high-speed and precision devices.

Industrial conditions often involve humidity, temperature variations, or exposure to chemicals. Poor resistance may shorten equipment life and increase risks.

Stainless Steel Balls (304, 316, 440C)

Offer a balance of strength and corrosion resistance; 316 is especially suited for acidic or alkaline environments.

Plastic Balls (POM, PTFE, PEEK)

Excellent chemical resistance and lightweight, often used in valves, testing equipment, or non-magnetic applications.

Glass Balls

Resistant to chemicals and electrically insulating, ideal for optical and laboratory instruments.

Cost is always a decisive factor, especially in large-scale or mid-to-low-end applications.

Carbon Steel Balls

Economical choice for industries with lower precision and durability demands, such as toys and conveyors.

Brass & Copper Balls

Provide good electrical conductivity and corrosion resistance, widely used in low-voltage electrical applications.

Aluminum Balls

Lightweight and affordable, used in decoration and light industry.

Cost-effectiveness should focus not only on the unit price but also on the long-term balance of performance and maintenance.

High-speed bearings → GCr15 steel or ceramic balls for strength and wear resistance.

Food processing industry → 316 stainless steel balls for hygiene and corrosion resistance.

Toy manufacturers → Carbon steel balls for large-scale cost-effective production.

Chemical equipment → Plastic or glass balls for superior chemical resistance.

The Golden Triangle Principle does not mean pursuing only one extreme feature. Instead, it guides companies to strike the right balance between strength, corrosion resistance, and cost according to actual needs. As a professional B2B manufacturer and supplier, we provide a full range of ball materials — from stainless steel, bearing steel, carbon steel, brass, aluminum, tungsten carbide, ceramic, plastic, to glass — along with tailored technical support and selection advice to help clients achieve the best balance between quality and cost.

View More(Total0)Comment Lists