Home > News

Home > News

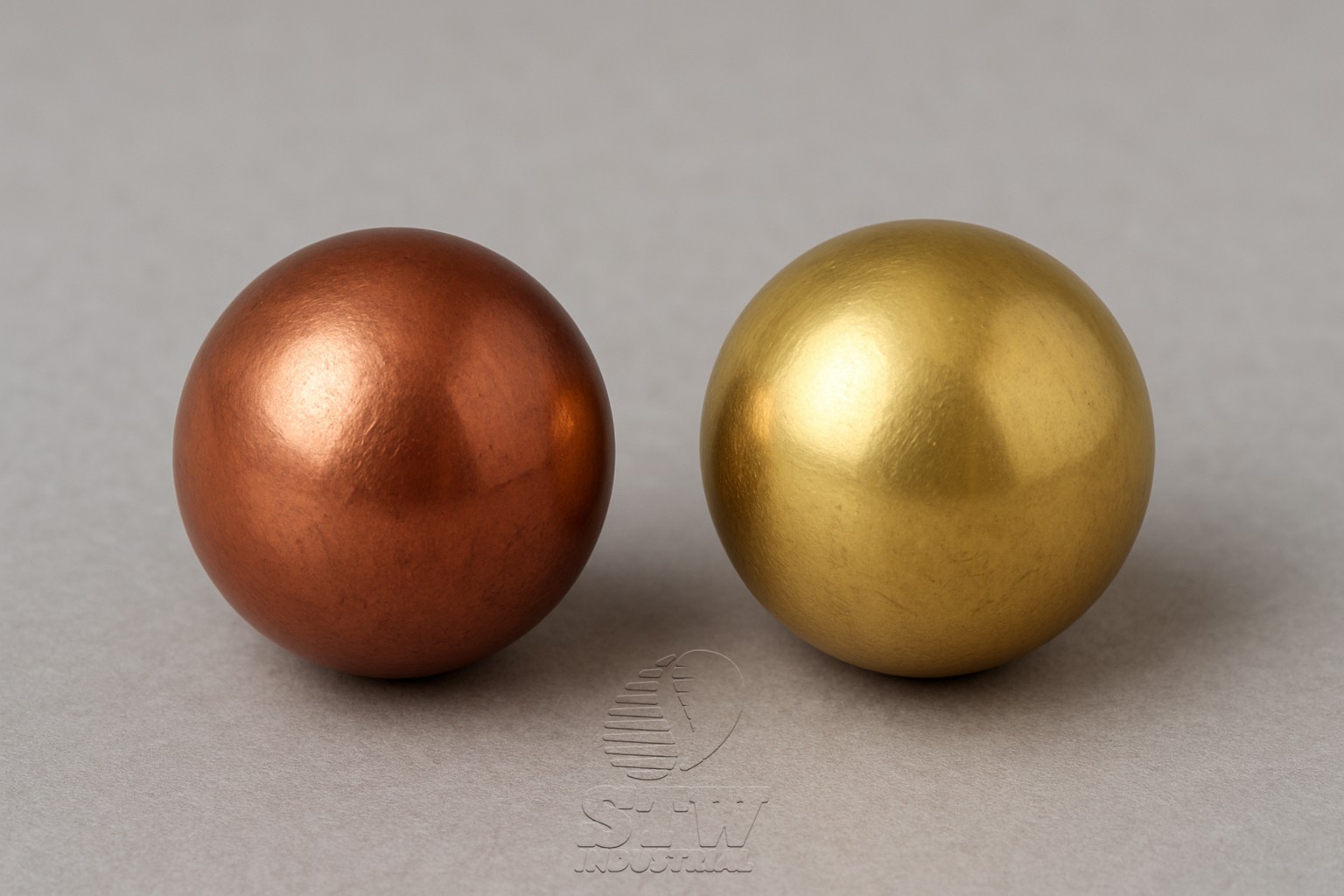

As the electrical industry continues to evolve at high speed, the selection of materials plays a vital role in ensuring equipment performance, safety, and service life. Among these materials, copper balls—especially red copper balls and brass balls—stand out for their unique electrical and mechanical properties, becoming increasingly indispensable in a wide range of electrical applications.

Copper is renowned for its excellent electrical and thermal conductivity, second only to silver. It also offers good ductility, corrosion resistance, and workability. Copper balls are generally categorized into:

Red Copper Balls: Contain over 99.9% pure copper. They offer outstanding electrical conductivity, making them ideal for high-precision, electricity-sensitive applications.

Brass Balls: A copper-zinc alloy. While slightly lower in conductivity than red copper, brass balls offer superior strength and corrosion resistance, making them suitable for structural electrical components.

Red copper balls are commonly used in precision switches and electrical contacts due to their excellent conductivity and wear resistance, ensuring stable current transmission and fast response.

In electronic modules, copper balls often serve as part of the conductive path or contact point. Their size stability and oxidation resistance are crucial in miniature, high-density devices.

Brass balls are widely used in high-voltage surge protectors and grounding systems for their mechanical durability and excellent corrosion resistance, ensuring long-term reliable performance.

Copper balls are embedded as key components in relays and solenoid valves, enhancing electromagnetic response speed and extending device lifespan.

| Property | Red Copper Ball | Brass Ball | Stainless Steel Ball | Plastic Ball |

|---|---|---|---|---|

| Conductivity | Excellent | Good | Moderate | Poor |

| Corrosion Resistance | Good | Excellent | Excellent | Fair |

| Mechanical Strength | Moderate | Good | Excellent | Low |

| Cost | Medium | Medium | High | Low |

From the table above, it is clear that copper balls strike an optimal balance between conductivity, corrosion resistance, and cost, making them an ideal material in large-scale and precision electrical applications.

As a professional B2B manufacturer and exporter of precision balls, we offer top-quality red copper and brass balls with the following features:

Premium Raw Materials: High-purity copper for superior conductivity.

Precision Machining: Custom tolerances up to ±0.01mm to meet high-end application requirements.

Surface Treatment Options: Polishing, passivation, plating, and more for enhanced durability and corrosion resistance.

Wide Range of Sizes: Standard models in stock and customizable sizes available.

Copper balls are not only critical in current electrical industry applications but also show great potential in emerging fields such as new energy, electric vehicles, and smart electronics. If you're looking for stable, reliable, and cost-effective copper ball solutions, we’re here to help with professional support and consistent quality.

View More(Total0)Comment Lists